Technologies and know-how

Control

Proven quality for reliable processes and products

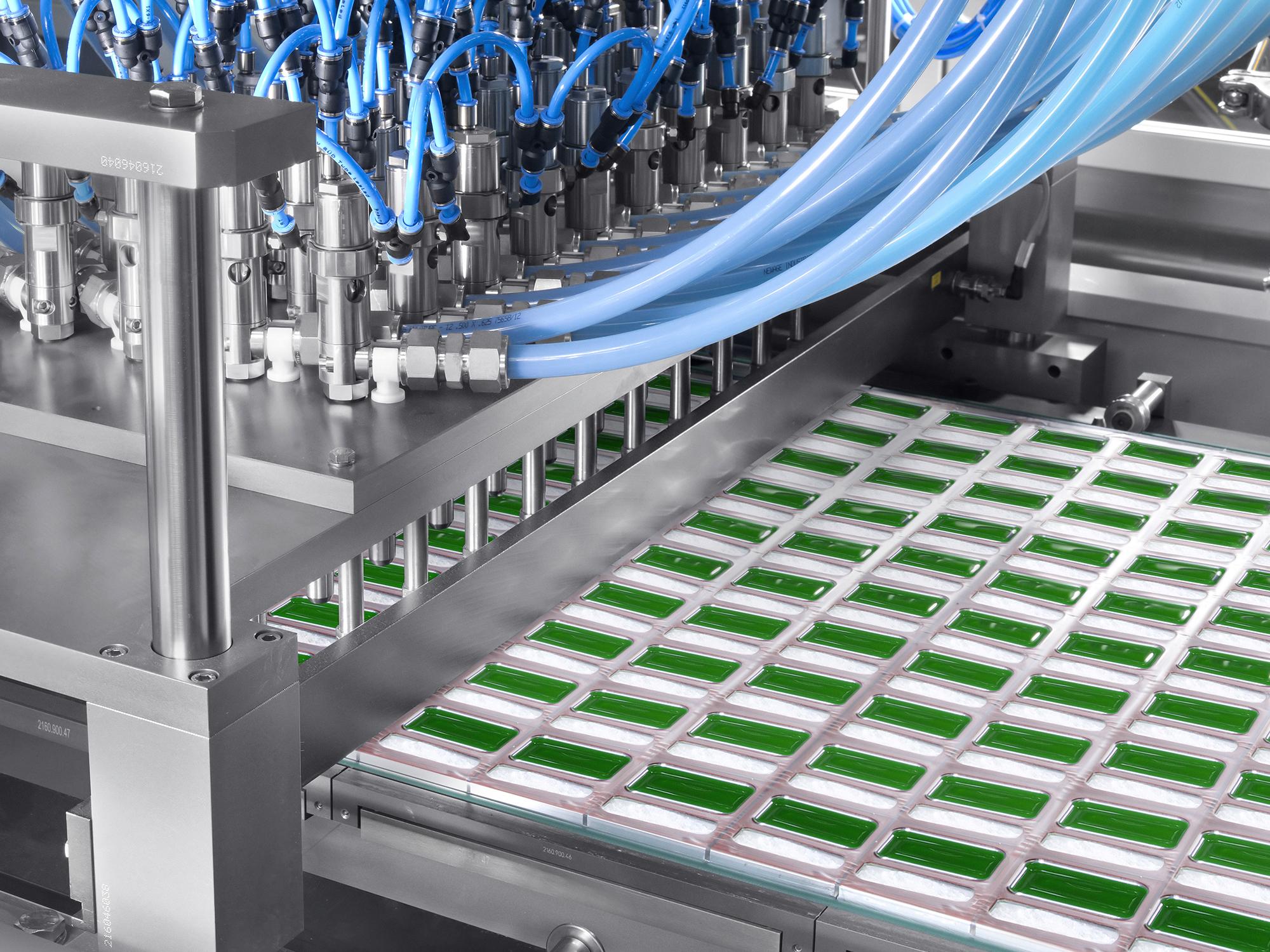

What does it take to manufacture products with consistently top quality and quantity? Process reliability – whether for medical devices, pharmaceutical products, or consumer goods. We ensure this reliability with 100% control. Using integrated, highly advanced sensor, weighing, and camera technology, as well as X-ray technology. The systems verify – with short control times, smooth feeding, gentle transportation – exact dosing and precise assembly. Deviations are reliably detected, ensuring that only good products are passed on to the next process step. Another part of the monitoring spectrum: Tools for analysis and documentation, as well as statistical in-process control (IPC) of random samples during the production of your pharmaceutical products.

Our expterise

Perfectly aligned system solutions

In focus: Your product

Monitoring force, displacement and torque during the assembly of injection pens, measuring residual oxygen in sterile-filled IV bags, and checking the seal quality in ostomy systems. 100% control of pharmaceutical capsules with good-bad sorting using our patented rotary star principle. Your product defines the process. And therefore also the control technologies for process reliability and product quality. We complement rule-based image processing with deep learning methods to optimize quality control. This enables even better and faster detection of defects, such as sections with uneven coating in microneedle systems.

Capsules

Hard capsules are among the most versatile pharmaceutical forms. We bring our process expertise to bear for precise filling. We offer machines from development to production, along with dosing methods for various solid and liquid media.