Technologies and know-how

Dosing and filling

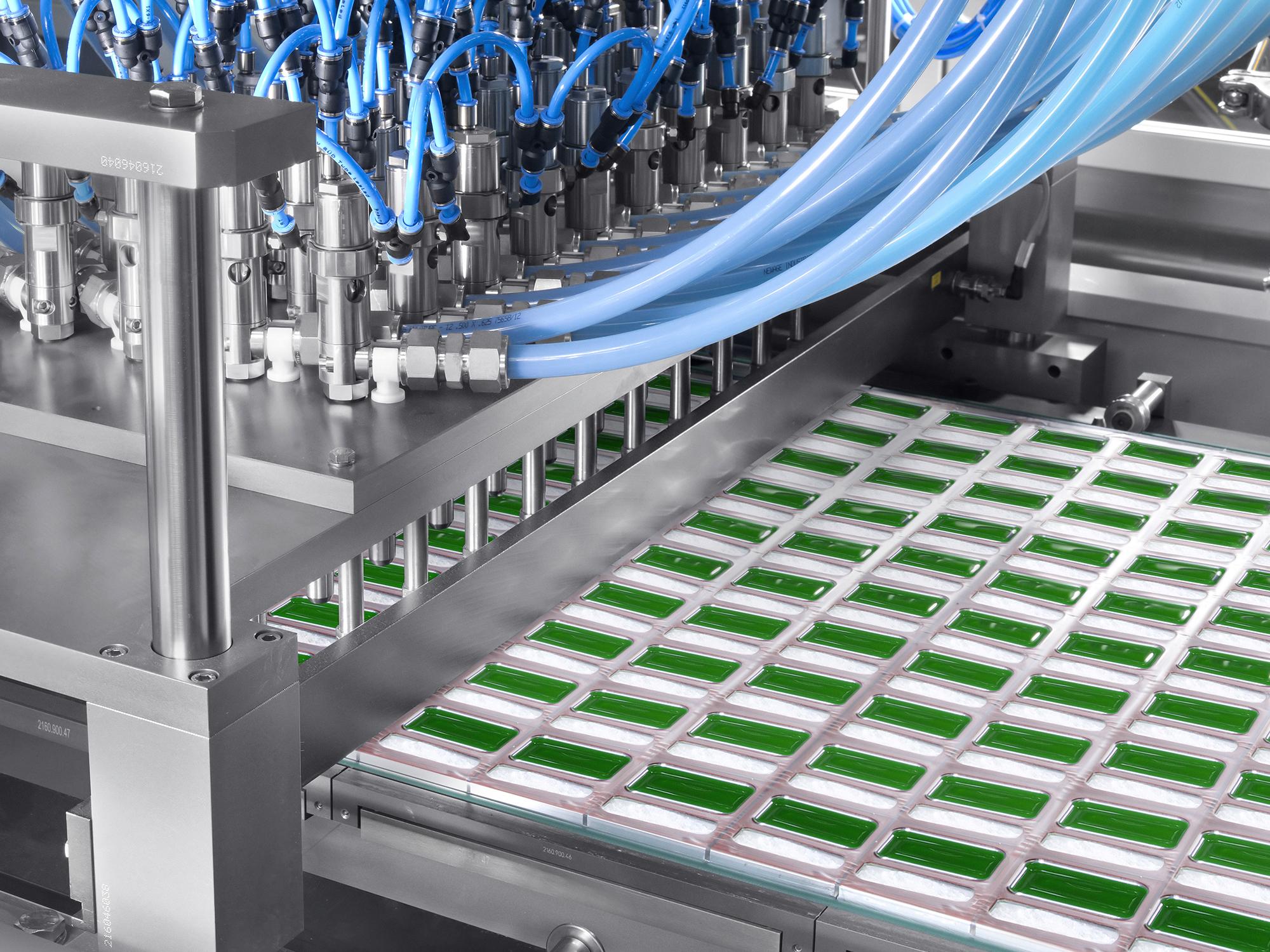

Reproducible precision for every product and medium

Whether manually in the lab and galenics, semi-automated for small series, or fully automated for high output: dosing and filling processes from Harro Höfliger ensure repeatable, exact results. Throughout the lifecycle of your product. Our technologies cover all media – powders, liquids, lyo beads, or solid materials. With dosing from micro to macro, with partial or complete filling of the devices. Precise control and monitoring of the dosing process ensures that quality standards are consistently met – which is crucial for market approval and the success of your product.

Our expertise

Perfectly aligned system solutions

in focus: Your product

Dry powders for inhalers, various filling materials in capsules, reagents for diagnostics, liquids for portion packs, sterile preparations for infusions: Your product defines the process. Here we not only integrate technologies for dosing and filling but also coordinate control systems for consistent product quality. For determining the mass of powders and other solid formulations, an AMV (Advanced Mass Verification) sensor, for example. It can be used independently of the dosing system and detects the product non-destructively at full machine speed.

Capsules

Hard capsules are among the most versatile pharmaceutical forms. We bring our process expertise to bear for precise filling. We offer machines from development to production, along with dosing methods for various solid and liquid media.

Projects and innovations with Harro Höfliger

Successful projects

Medical Technologies

Gentle handling of lyo bead pellets

For the handling of lyophilisates, Harro Höfliger offers a unique automated solution – the Lyo Bead Dispenser. The freeze-dried pellets are safely conveyed and accurately dosed via air flow.

Pharmaceutical Technologies

High-performance production of a special capsule solution

With the Accordion Pill®, Intec Pharma has developed an innovative capsule platform that provides continuous drug release. The manufacturing technology for the product was supplied by Harro Höfliger.

Pharmaceutical Technologies

Sterile filling of infusion bags

New B Innovation Limited (New β Innovation) uses a partially automated aseptic filling and sealing line for pre-sterilized infusion bags.

Pharmaceutical Technologies

Re-usable Inhaler Respimat®

Since 2004, the Respimat® has been ensuring easy inhalation for patients with diseases such as asthma and COPD. In 2019, Boehringer Ingelheim launched the re-usable version of this inhaler.